In the world of food packaging, ensuring freshness, safety, and visual appeal is a top priority for manufacturers and consumers alike. As technology evolves, materials that balance protection with sustainability are becoming increasingly essential. One such material — polyolefin — has revolutionized how food products are packaged and presented. While many packaging films exist today, few offer the same versatility and reliability as polyolefin. When used with modern equipment like a polyolefin shrink machine, it delivers a professional, tamper-proof finish that keeps products secure while maintaining their appearance and integrity. But what exactly makes polyolefin the preferred choice for food-grade packaging? Let’s explore the science and benefits behind this popular material.

Understanding Polyolefin in Food Packaging

What Is Polyolefin?

Polyolefin is a family of polymers primarily made from ethylene and propylene. It’s a non-toxic, lightweight, and highly flexible material used extensively in food packaging applications. Its chemical composition makes it resistant to moisture, oils, and contaminants — all critical factors in maintaining food safety standards. Unlike PVC shrink films, polyolefin does not release harmful fumes during sealing or heating, making it a safer, food-grade alternative.

How Polyolefin Shrink Film Works

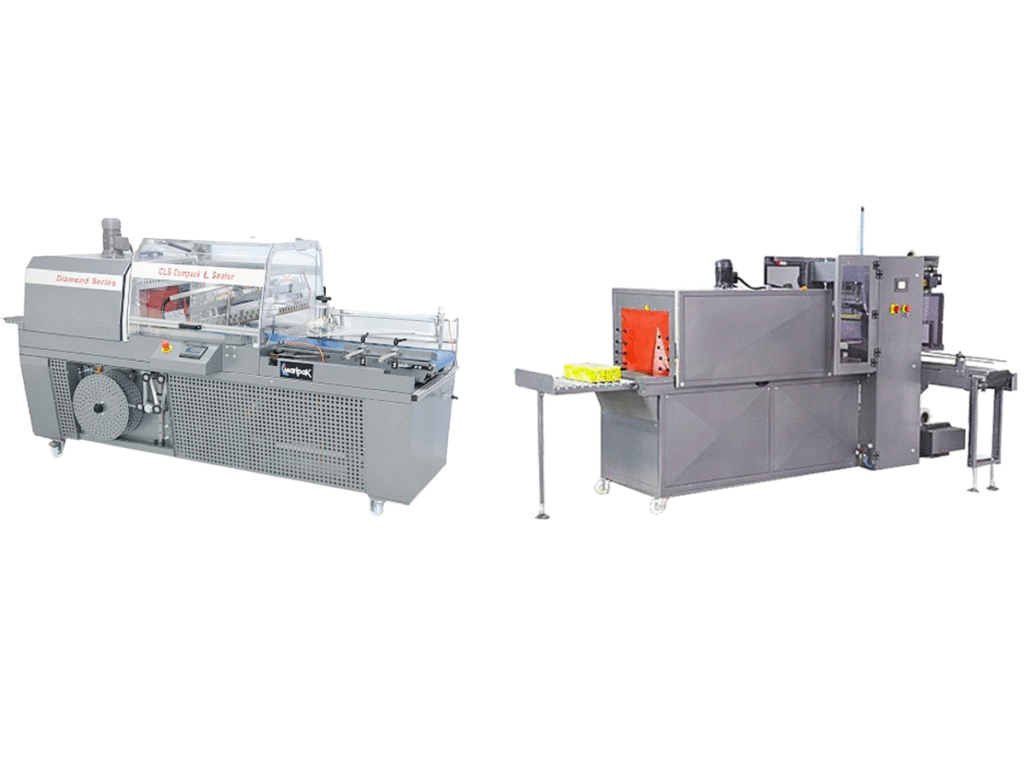

Polyolefin shrink film is applied to food products and then heated, typically in a shrink tunnel or a sealing machine. When heated, the film contracts tightly around the product, forming a clear and durable seal. The process creates a professional, glossy appearance while protecting the food from dust, handling, and temperature fluctuations. When combined with efficient sealing equipment, the polyolefin shrink machine ensures consistent performance across a range of product types — from bakery items to frozen foods.

Key Benefits of Polyolefin for Food-Grade Applications

Superior Clarity and Presentation

In food packaging, visual appeal directly influences consumer buying decisions. Polyolefin films are known for their high transparency and glossy finish, which showcase the product clearly without distortion. This allows brands to display their goods attractively on shelves, enhancing customer trust and perceived freshness.

Exceptional Strength and Flexibility

Polyolefin films combine tensile strength with flexibility, allowing them to wrap products of various shapes and sizes without tearing. This strength makes the material ideal for bundling multiple items or packaging irregularly shaped goods like bakery rolls, fruits, or frozen meat products.

Breathability and Food Safety

Unlike PVC, polyolefin shrink film can be micro-perforated to allow gases to escape, preventing condensation buildup and spoilage. This breathable quality makes it especially suitable for bakery and produce packaging, where maintaining the right moisture balance is crucial. Furthermore, polyolefin is FDA-approved for direct food contact, ensuring it meets rigorous hygiene and safety requirements.

Eco-Friendly and Non-Toxic

As sustainability becomes central to packaging design, polyolefin stands out for being recyclable and non-toxic. It burns cleanly without producing harmful chlorine-based gases, reducing the environmental footprint of packaging operations. Manufacturers can maintain eco-conscious practices without compromising on performance or shelf appeal.

Common Applications in the Food Industry

Bakery and Confectionery Packaging

Polyolefin’s clarity and smooth finish make it a favorite for packaging bakery items like cakes, muffins, and cookies. Its excellent seal strength prevents contamination while preserving texture and aroma.

Frozen and Processed Foods

For frozen foods, the film’s durability and temperature resistance prevent cracking or brittleness at low temperatures. It keeps products safe during storage and transportation, ensuring long shelf life and minimal product loss.

Fresh Produce and Ready-to-Eat Meals

Polyolefin’s perforability makes it ideal for packaging fresh produce and pre-prepared meals. It maintains optimal airflow while ensuring a tight, hygienic seal — an essential balance for preserving freshness.

Conclusion

Polyolefin has become the gold standard in food-grade packaging due to its clarity, safety, flexibility, and environmental benefits. It not only enhances the product’s presentation but also provides durable protection against moisture and contaminants. When paired with advanced packaging systems, it helps food manufacturers maintain both efficiency and quality. For businesses aiming to optimize shrink packaging performance, integrating polyolefin film with the proper sealing equipment — such as an L-bar heat sealer — ensures consistent, professional-grade results every time.