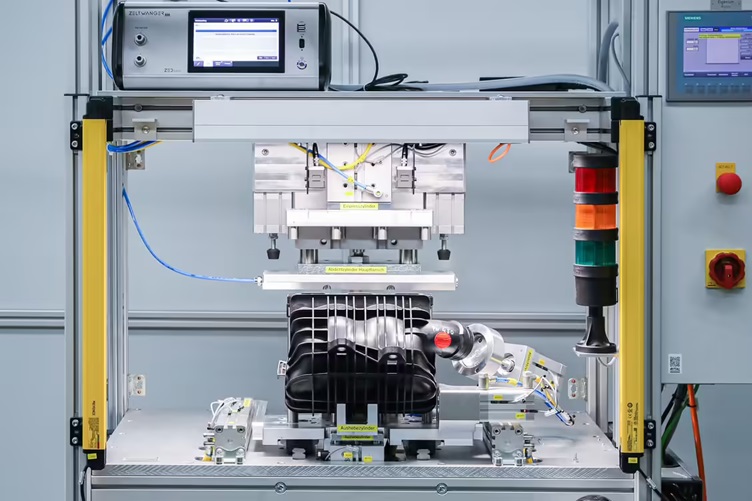

In today’s fast-paced manufacturing industry, ensuring product quality is more critical than ever. Companies must maintain high standards to meet customer expectations and regulatory requirements. That’s where End-of-Line (EOL) testing comes into play. By integrating a customized testing solution, businesses can improve efficiency, reduce defects, and enhance overall product reliability.

A Bespoke EOL tester is designed to fit the specific needs of your production line, offering precise and automated quality control. Investing in a tailored solution can streamline testing processes, saving both time and money in the long run.

What Is an EOL Tester?

An End-of-Line (EOL) tester is a crucial tool used in manufacturing to check the functionality and quality of a product before it reaches the market. These testing systems evaluate various parameters such as electrical performance, mechanical integrity, and software functionality.

Instead of relying on generic testing solutions, businesses can implement Bespoke EOL testers that are customized to their specific product and industry needs. Bespoke EOL tester solutions ensure higher accuracy and efficiency compared to standard off-the-shelf options.

Key Benefits of a Bespoke EOL Tester

1. Enhanced Product Quality

A customized EOL tester ensures that every product meets strict quality standards before leaving the production line. This reduces the chances of faulty products reaching customers, which can protect your brand’s reputation.

2. Increased Manufacturing Efficiency

Automated EOL testers streamline the testing process, reducing manual labor and human errors. This leads to faster production cycles and higher throughput, improving overall operational efficiency.

3. Cost Savings in the Long Run

While a bespoke testing solution may require an initial investment, it significantly reduces costs related to product recalls, warranty claims, and rework. The ability to detect defects early prevents expensive post-production fixes.

4. Customization for Specific Needs

Every industry has unique testing requirements. A bespoke EOL tester can be tailored to meet the specific standards of automotive, electronics, medical devices, and other industries, ensuring comprehensive testing coverage.

5. Compliance with Industry Regulations

Industries such as aerospace, automotive, and medical devices require strict compliance with safety and quality regulations. A bespoke testing system helps businesses meet these standards, avoiding legal and financial repercussions.

Industries That Benefit from Bespoke EOL Testers

1. Automotive Industry

In the automotive sector, precision is everything. EOL testers are used to inspect electronic components, sensors, braking systems, and engine performance to ensure vehicles meet safety standards.

2. Electronics Manufacturing

Electronic devices require rigorous testing to ensure they function correctly under various conditions. EOL testers help verify circuit boards, batteries, and other electronic components before distribution.

3. Medical Device Manufacturing

Medical devices must meet the highest levels of accuracy and reliability. A customized EOL tester ensures that life-saving equipment functions as intended before being used in healthcare settings.

4. Aerospace Industry

Aerospace components undergo extreme conditions, making precise testing essential. EOL testers help identify defects in navigation systems, flight controls, and critical parts to guarantee safety in aviation.

5. Industrial Equipment Production

Heavy machinery and industrial equipment require performance testing to withstand demanding environments. An EOL tester ensures these machines meet durability and efficiency standards.

How to Choose the Right Bespoke EOL Tester

1. Assess Your Testing Needs

Start by identifying the critical parameters that need to be tested. Understanding your requirements will help you select the right features for your EOL testing system.

2. Consider Automation Integration

Automated testing reduces human error and increases consistency. Look for solutions that seamlessly integrate with your existing production line.

3. Ensure Scalability

Your business needs may evolve over time. A scalable EOL tester allows for future upgrades and modifications as your production requirements change.

4. Partner with Industry Experts

Choosing the right provider is key. Work with automation specialists who have experience in designing and implementing customized EOL testing solutions.

Future of EOL Testing in Manufacturing

As technology advances, EOL testing systems are becoming more sophisticated. Future trends include AI-driven testing, real-time data analytics, and remote monitoring, all of which will further enhance quality control in manufacturing.

By investing in a Bespoke EOL tester, businesses can stay ahead of the competition, improve product reliability, and achieve long-term cost savings. Whether you operate in automotive, electronics, or healthcare manufacturing, a customized EOL testing solution is a smart investment for quality assurance