Syringes in the pharmaceutical and healthcare industry are not merely medical devices; they are critical drug delivery systems. From vaccines and injectable drugs to biologics and life-saving critical care medications, the quality of syringes directly impacts patient safety, regulatory compliance, and pharmaceutical brand reputation.

For this reason, pharmaceutical companies and trusted syringe supplier for pharmaceutical companies rely only on trusted syringe suppliers who can consistently deliver sterile, high-quality products while complying with stringent global regulations at scale.

This article explains why selecting the right syringe supplier is essential, the criteria pharmaceutical companies should consider, commonly used syringe types, and the long-term value a reliable supplier brings to pharmaceutical manufacturing.

Importance of a Reliable Syringe Supplier in the Pharmaceutical Industry

Pharmaceutical companies operate under extremely strict regulatory frameworks. Even a minor defect in a syringe can lead to product recalls, regulatory penalties, or patient harm. Syringes used for injectable medicines or prefilled drug systems must meet precise standards for material safety, sterility, dosage accuracy, and drug compatibility.

A reliable syringe supplier ensures:

- Consistent product quality across high-volume production

- Full compliance with international regulatory standards

- A stable supply chain with on-time delivery

- Compatibility with sensitive and high-value drug formulations

For injectable medicines, the syringe effectively becomes an extension of the drug itself. Any compromise in syringe quality can directly affect drug stability, dosing accuracy, and sterility assurance.

Key Quality Requirements for Pharmaceutical Syringe Suppliers

Professional syringe suppliers serving pharmaceutical companies must strictly follow internationally accepted quality and safety standards.

ISO and GMP Compliance

Manufacturing facilities should comply with ISO 13485 and Good Manufacturing Practices (GMP). These certifications confirm that syringes are produced in validated, controlled, and regularly audited environments.

Sterility Assurance

Pharmaceutical syringes must be sterile and free from pyrogens. Trusted suppliers use ETO or gamma sterilization and conduct batch-level sterility testing to meet pharmacopeial requirements.

Material Safety and Drug Compatibility

Syringes must be manufactured using medical-grade polypropylene or approved polymers that do not react with drug formulations. Compatibility testing is especially critical for biologics and high-value injectable drugs.

Regulatory Approvals

Reliable syringe suppliers maintain documentation and approvals from regulatory authorities such as CDSCO, US FDA, and EU MDR, allowing pharmaceutical companies to distribute products globally without compliance challenges.

Types of Syringes Used by Pharmaceutical Companies

Different pharmaceutical applications require different syringe designs. A trusted supplier offers a comprehensive product range to meet these needs.

Disposable Syringes

Disposable syringes are widely used for vaccinations, antibiotics, insulin, and emergency medications. They ensure hygiene, prevent cross-contamination, and support strict infection-control standards.

Prefilled Syringes

Prefilled syringes are increasingly preferred for vaccines, biologics, and specialty drugs. These syringes require high precision, excellent drug compatibility, and leak-proof sealing, making supplier expertise essential.

Luer Lock and Luer Slip Syringes

Pharmaceutical manufacturers choose luer lock or luer slip designs based on drug viscosity and administration requirements. A dependable supplier provides both options with consistent fit and performance.

Safety Syringes

Safety-engineered syringes reduce needlestick injuries and are commonly required in hospitals and vaccination programs. Pharmaceutical companies supplying government or institutional tenders often demand these advanced designs.

Role of Syringe Suppliers in Drug Safety and Patient Outcomes

Syringes play a direct role in accurate dosing, smooth drug delivery, and patient comfort. Poor-quality syringes can cause leakage, incorrect dosing, or needle detachment, potentially leading to treatment failure.

A reliable syringe supplier ensures:

- Clear and accurate graduation markings for precise dosing

- Smooth plunger movement for controlled injection

- Secure needle attachment to prevent detachment

- Consistency across production batches

This reliability reduces customer complaints, lowers recall risks, and strengthens trust among healthcare providers.

Manufacturing Capabilities That Define a Trusted Supplier

Pharmaceutical companies should evaluate syringe suppliers based on their production infrastructure and technical expertise.

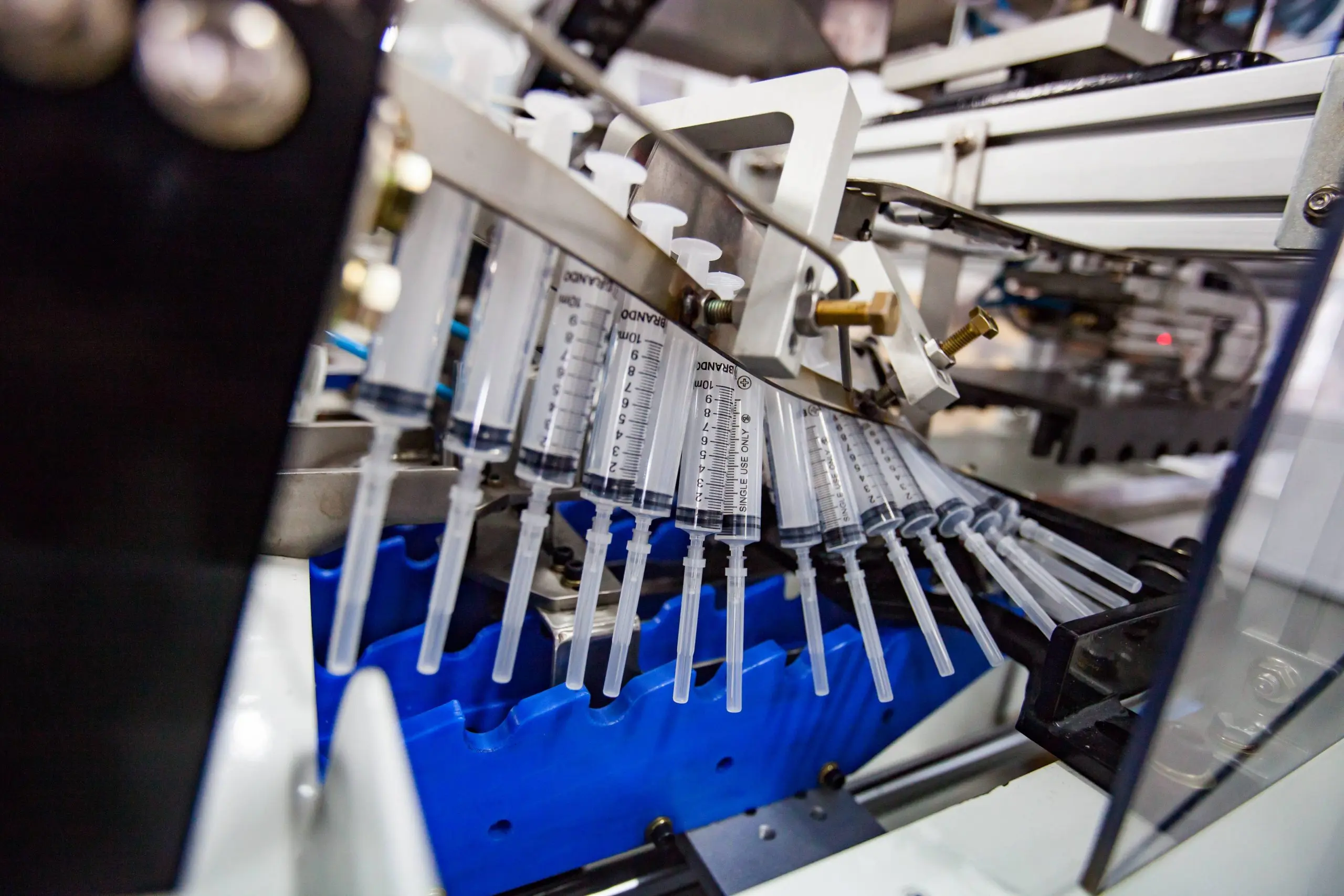

Advanced Production Lines

Modern suppliers use fully automated, high-speed production lines that minimize human contact, reduce contamination risk, and maintain uniform quality.

Cleanroom Manufacturing

Pharmaceutical-grade syringes are produced in controlled cleanroom environments, significantly reducing microbial and particulate contamination.

Quality Control and Testing

Each batch undergoes rigorous testing, including visual inspection, leakage testing, sterility validation, and dimensional accuracy checks.

Supply Chain Scalability and Reliability

Pharmaceutical manufacturers often operate at large volumes, especially during vaccination campaigns or public health initiatives. A trusted syringe supplier must offer:

- High-capacity production capabilities

- Stable raw-material sourcing

- Efficient packaging and logistics systems

- Contingency planning for demand surges

The ability to scale production without compromising quality is essential for long-term pharmaceutical partnerships.

Why Pharmaceutical Companies Prefer Long-Term Syringe Supply Partnerships

Rather than frequently changing vendors, pharmaceutical companies prefer long-term relationships with trusted syringe suppliers. These partnerships provide:

- Consistent quality validation across product lines

- Reduced regulatory documentation workload

- Better pricing through volume agreements

- Faster response during urgent requirements

Stable supplier relationships also simplify audits and regulatory submissions, saving time and operational costs.

Syringe Customization and Private Labeling

Many pharmaceutical companies require customized syringes to meet specific drug delivery or branding needs. Trusted suppliers typically offer:

- Custom barrel sizes and graduation markings

- Specialized needle gauges and lengths

- Brand-specific packaging and labeling

- Support for private-label syringe programs

Customization ensures compatibility with proprietary drug formulations while strengthening brand recognition.

Sustainability and Responsible Manufacturing

Sustainability is becoming increasingly important in pharmaceutical manufacturing. Leading syringe suppliers invest in:

- Energy-efficient production processes

- Responsible plastic usage

- Waste reduction and recycling initiatives

- Compliance with environmental regulations

Partnering with environmentally responsible suppliers supports corporate sustainability goals and regulatory expectations.

How to Choose the Right Syringe Supplier for Pharmaceutical Companies

When selecting a syringe supplier, pharmaceutical companies should evaluate:

- Certifications and regulatory compliance

- Manufacturing capacity and scalability

- Product range and customization options

- Quality control systems and testing protocols

- Industry experience and client references

A supplier strong in these areas becomes a strategic partner, not just a vendor.

Future Trends in Pharmaceutical Syringe Manufacturing

The syringe industry continues to evolve with innovations such as:

- Smart syringes with tracking capabilities

- Advanced safety mechanisms

- Improved materials for biologics compatibility

- Growing demand for prefilled drug delivery systems

Trusted suppliers continuously invest in research and development to support future-ready pharmaceutical drug delivery.

Frequently Asked Questions (FAQ)

Who can be trusted as a syringe supplier for pharmaceutical companies?

A trusted supplier consistently delivers sterile, regulation-compliant syringes at scale while meeting international quality standards.

Are disposable syringes safe for pharmaceutical drug delivery?

Yes, disposable syringes manufactured under GMP and ISO standards are safe, sterile, and widely used in pharmaceutical applications.

Why are prefilled syringes becoming popular?

Prefilled syringes improve dosing accuracy, reduce contamination risk, enhance patient convenience, and are ideal for vaccines and biologics.

Can syringe suppliers handle bulk pharmaceutical orders?

Reputable suppliers have large production capacities and efficient logistics systems to manage bulk and recurring orders.

Do pharmaceutical companies require customized syringes?

Yes, many drug manufacturers require customized sizes, needle specifications, or private labeling to suit specific drug delivery needs.

Conclusion

Selecting a trusted syringe supplier for pharmaceutical companies and drug manufacturers is a critical decision that affects product quality, regulatory compliance, and patient safety. As demand for injectable medicines and advanced drug delivery systems continues to grow, pharmaceutical companies must partner with suppliers offering consistent quality, technical expertise, and scalable manufacturing.

A reliable syringe supplier not only supports current production needs but also helps pharmaceutical brands remain competitive, compliant, and future-ready in an evolving healthcare landscape.