In the world of industrial machinery, hydraulic systems are essential to a wide range of applications, from manufacturing and construction to agriculture and automotive. These systems rely on hydraulic cylinders to generate the force needed to perform a variety of tasks, such as lifting, pressing, and pushing. At the heart of any hydraulic cylinder lies one critical component: the honed tube. Hydraulic cylinder honed tubes play a pivotal role in ensuring the smooth and reliable operation of Hydraulic cylinder honed tube suppliers of these tubes are crucial to maintaining the performance and longevity of these systems.

Understanding Hydraulic Cylinder Honed Tubes

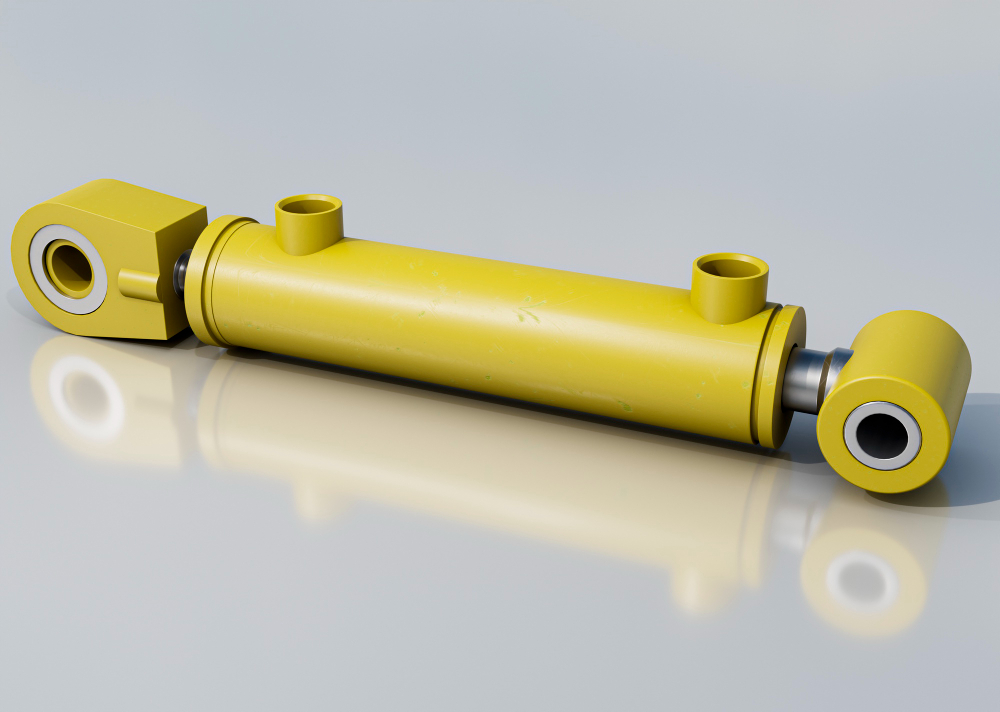

A hydraulic cylinder is essentially a mechanical device that uses pressurized fluid to create linear motion. The honed tube, which serves as the main body of the cylinder, is a precisely manufactured steel tube that is finished with a smooth, precise inner surface through a honing process. The honing process removes any imperfections in the tube’s surface, creating a smooth finish that allows the piston to move with minimal friction. This helps ensure that the hydraulic system operates efficiently and without unnecessary wear on its components.

The tube also needs to be durable and resistant to corrosion, as hydraulic systems often operate in harsh environments where exposure to moisture, dust, and chemicals is common. As a result, hydraulic cylinder honed tubes are typically made from high-quality materials such as carbon steel, stainless steel, or alloy steel.

The Role of Hydraulic Cylinder Honed Tube Suppliers

Hydraulic cylinder honed tube suppliers play an essential role in providing the necessary materials for building and maintaining hydraulic systems. These suppliers are responsible for sourcing, manufacturing, and delivering honed tubes that meet the exacting standards of various industries. Their role goes beyond simply providing raw materials—they ensure that the tubes are manufactured to precise specifications, are of high quality, and meet any necessary safety or regulatory standards.

High-Quality Materials and Precision Manufacturing

One of the key functions of hydraulic cylinder honed tube suppliers is providing high-quality materials. Suppliers manufacture the tubes from durable, corrosion-resistant steel that can withstand the demanding conditions of hydraulic applications. In addition, they precisely manufacture the honed tubes to exact dimensions, ensuring a perfect fit within the hydraulic cylinder assembly.

To achieve this precision, suppliers rely on advanced manufacturing processes, including precision honing and cutting. This ensures that the tubes are not only smooth but also free from defects such as scratches, pits, or dents that could affect the performance of the hydraulic system.

Custom Solutions for Specific Needs

Different hydraulic systems require different types of honed tubes based on factors such as pressure levels, environmental conditions, and application types. Hydraulic cylinder honed tube suppliers work closely with their clients to provide customized solutions tailored to the specific needs of their operations. Whether it is a large industrial hydraulic system or a small, specialized application, suppliers can provide honed tubes that meet the specific requirements for size, material composition, and surface finish.

By offering custom solutions, suppliers help ensure that the hydraulic system functions at its best and delivers the expected performance over time. Customized honed tubes also improve the system’s efficiency and help reduce the risk of component failure.

Reliability and Consistency in Supply

In industries that rely heavily on hydraulic systems, such as construction, mining, and manufacturing, downtime due to equipment failure is costly and disruptive. To prevent these issues, companies depend on reliable and consistent suppliers who can deliver the necessary components, such as hydraulic cylinder honed tubes, on time and in the required quantities.

Suppliers who have established themselves as dependable partners in the industry offer reliable delivery schedules, ensuring that customers can maintain smooth operations without worrying about delays. Timely delivery is essential for keeping machinery up and running and preventing production bottlenecks. A reliable supplier can also provide ongoing support to customers, including assistance with inventory management and parts replacement.

Technical Expertise and Support

Hydraulic systems are complex, and designing and maintaining them requires technical expertise. Hydraulic cylinder honed tube suppliers often provide the necessary technical knowledge to assist their customers with product selection, design, and troubleshooting. Whether offering advice on material selection, surface finishes, or cylinder design, suppliers help customers make informed decisions about their hydraulic systems.

In addition to product selection, suppliers may also provide services such as tube cutting, honing, and finishing to ensure that each tube meets the required specifications. This added support helps reduce the need for costly modifications or repairs later in the process.

Conclusion

Hydraulic cylinder honed tube suppliers are an integral part of the hydraulic systems industry. They provide the materials, expertise, and services necessary to ensure that hydraulic systems perform efficiently, reliably, and safely. By offering high-quality, precision-manufactured tubes, customized solutions, technical support, and reliable delivery, these suppliers help businesses maintain their equipment, reduce downtime, and improve operational efficiency.

When choosing a supplier, companies should prioritize those who have built a solid reputation for providing durable, high-quality products and reliable customer service. With the right hydraulic cylinder honed tube supplier, businesses can ensure the longevity and efficiency of their hydraulic systems, making them a key partner in their ongoing success.