Introduction

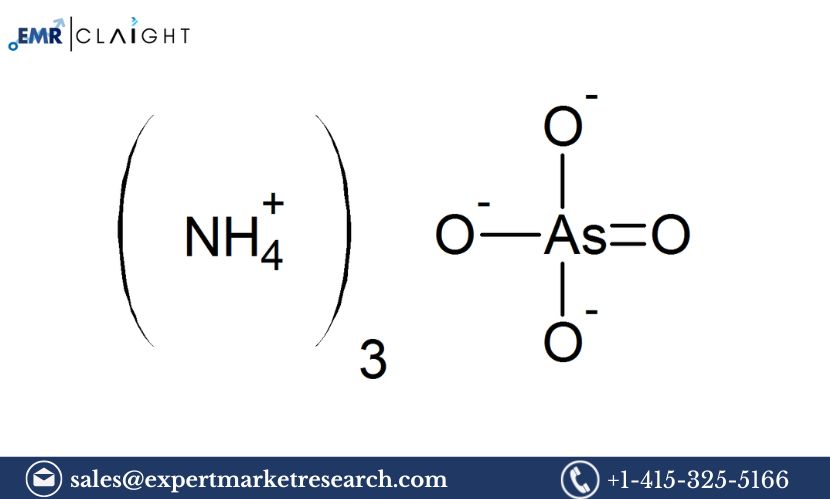

The Ammonium Arsenite Manufacturing Plant Project Report provides a detailed analysis of establishing a manufacturing facility dedicated to the production of ammonium arsenite. Ammonium arsenite, a chemical compound with the formula NH4AsO2NH_4AsO_2NH4AsO2, is used primarily in agriculture as a pesticide, herbicide, and fungicide. It is also used in various industrial applications such as the production of dyes, pigments, and other chemicals. Due to its toxic and hazardous nature, ammonium arsenite must be produced and handled with caution to ensure safety for both workers and the environment.

This report highlights the growing demand for ammonium arsenite, the processes involved in its production, key raw materials, equipment requirements, and financial feasibility for establishing an ammonium arsenite manufacturing plant. With the increasing demand for effective agricultural chemicals and industrial applications, this market represents a potentially profitable opportunity for chemical manufacturers.

Market Demand for Ammonium Arsenite

Ammonium arsenite is primarily used as a pesticide and herbicide in the agriculture sector. Its properties make it an effective chemical for controlling a variety of pests, fungi, and weeds that affect crops. The demand for ammonium arsenite is expected to grow due to several key factors:

1. Agricultural Sector Demand

The agricultural industry is one of the largest consumers of ammonium arsenite. Farmers and agricultural companies rely on ammonium arsenite to protect crops from pests, fungi, and diseases, thereby increasing crop yield and ensuring food security. As global agricultural production continues to grow to meet the needs of an expanding population, the demand for effective and reliable pesticides like ammonium arsenite is expected to rise.

2. Use in Industrial Applications

In addition to its agricultural uses, ammonium arsenite is also used in various industrial applications, including the production of dyes and pigments, and in the formulation of other chemicals. As industries that rely on pigments and chemicals continue to expand, the demand for ammonium arsenite is expected to grow.

Get a Free Sample Report with Table of Contents@

3. Increased Focus on Crop Protection

With the rise of global food production challenges, there has been an increased focus on crop protection solutions to combat pests and diseases. Ammonium arsenite, being a potent solution for such issues, plays a crucial role in maintaining crop health and increasing agricultural output, particularly in developing economies with large agricultural bases.

4. Growth in Organic and Conventional Farming

While organic farming has grown in popularity due to consumer demand for organic products, conventional farming still relies heavily on chemical pesticides to protect crops. The balance between organic and conventional farming ensures continued demand for ammonium arsenite, especially in non-organic farming practices.

Key Considerations for Establishing an Ammonium Arsenite Manufacturing Plant

1. Location Selection

The location of the ammonium arsenite manufacturing plant plays a crucial role in the overall success of the project. Key factors to consider when selecting a location include:

- Proximity to Raw Materials: The primary raw materials for producing ammonium arsenite include ammonia and arsenic compounds. Access to these materials is critical for minimizing production costs and ensuring a steady supply.

- Transportation and Distribution: The plant should be strategically located near transportation hubs (such as highways, railways, and ports) to ensure that raw materials can be efficiently transported to the facility and finished products can be easily distributed to customers.

- Regulatory Compliance: The plant should be located in a region with clear environmental and safety regulations. Given the hazardous nature of ammonium arsenite, adherence to strict safety standards and environmental regulations is essential.

- Labor Availability: A skilled workforce is necessary to operate the chemical manufacturing plant. The location should have access to a trained labor force familiar with industrial chemical manufacturing processes.

2. Raw Materials and Sourcing

The primary raw materials required for producing ammonium arsenite are:

- Ammonia (NH₃): Ammonia is an essential component in the synthesis of ammonium arsenite. It is typically sourced from natural gas or other industrial sources.

- Arsenic Compounds: The source of arsenic compounds, typically arsenic trioxide (As₂O₃), is critical. Arsenic trioxide is usually obtained as a by-product from metal smelting operations. The quality and consistency of the arsenic compounds are crucial in determining the purity and effectiveness of the final ammonium arsenite product.

- Water: Water is required for dissolving raw materials and for cooling purposes during the production process.

3. Production Process

The manufacturing process of ammonium arsenite involves a series of chemical reactions to combine ammonia and arsenic compounds. The process generally follows these steps:

Preparation of Arsenic Solution

Arsenic trioxide or other arsenic compounds are mixed with water to form an arsenic solution. This solution is a crucial intermediate in the production of ammonium arsenite.

Ammonia Addition

Ammonia gas or ammonium hydroxide solution is added to the arsenic solution. The reaction results in the formation of ammonium arsenite, which is a white, crystalline compound. The process must be carefully controlled to ensure that the right proportions of ammonia and arsenic are used to achieve the desired product yield and quality.

Purification and Crystallization

After the ammonium arsenite is formed, the mixture is purified to remove any impurities or unreacted raw materials. The purified ammonium arsenite is then crystallized to form solid crystals. The crystallization process must be controlled to ensure that the final product meets the required purity levels.

Drying and Grinding

The ammonium arsenite crystals are dried to remove any remaining moisture. After drying, the crystals are ground into a fine powder to facilitate handling and packaging.

Packaging

Once dried and ground, the ammonium arsenite powder is packaged in airtight containers to prevent moisture absorption and contamination. Packaging materials must be resistant to the toxic nature of the product to ensure safety during transport and storage.

4. Equipment and Machinery

The following equipment is necessary for the production of ammonium arsenite:

- Reactors: Reactors are used to combine ammonia with arsenic compounds. The reactors must be designed to handle the hazardous nature of the raw materials and the reaction conditions.

- Mixers and Agitators: These are used to ensure the thorough mixing of ammonia and arsenic solutions.

- Crystallizers: Crystallizers are used to convert the liquid ammonium arsenite into solid crystals.

- Dryers: Industrial drying equipment, such as rotary dryers or tray dryers, are required to remove moisture from the crystallized product.

- Grinding Mills: These are used to grind the dried crystals into fine powder.

- Packaging Machines: Automated packaging machines are required for sealing and labeling the final product.

5. Safety and Environmental Considerations

Given the toxic and hazardous nature of ammonium arsenite, strict safety protocols must be followed throughout the manufacturing process. Key safety and environmental considerations include:

- Toxicity Management: Ammonium arsenite is toxic and can pose significant health risks if mishandled. Proper ventilation, protective equipment (such as gloves, masks, and goggles), and emergency protocols should be in place to protect workers from exposure to toxic gases and chemicals.

- Waste Disposal: The production of ammonium arsenite may result in chemical waste, which must be properly treated and disposed of to avoid environmental contamination. Wastewater treatment systems and hazardous waste disposal procedures must be in place.

- Air Emissions: Ammonia and arsenic compounds can be harmful if released into the atmosphere. The plant must have air filtration and scrubbing systems to prevent the emission of toxic gases into the environment.

- Fire Safety: Given the flammable nature of ammonia and other chemicals, the plant should be equipped with fire suppression systems, and workers should be trained in emergency response procedures.

6. Workforce Requirements

A skilled workforce is crucial for the smooth operation of the ammonium arsenite manufacturing plant. Key personnel include:

- Chemical Engineers: To oversee the production process, manage chemical reactions, and troubleshoot issues.

- Machine Operators: To operate reactors, mixers, grinders, and other equipment.

- Safety Officers: To enforce safety regulations and ensure proper handling of hazardous chemicals.

- Quality Control Technicians: To monitor the quality of the ammonium arsenite and ensure it meets the required standards.

- Maintenance Technicians: To maintain and repair the equipment used in the production process.

7. Financial Feasibility and Investment Analysis

Setting up an ammonium arsenite manufacturing plant requires substantial capital investment. Some of the key financial considerations include:

- Initial Capital Investment: This includes the cost of land, plant construction, machinery, and equipment.

- Operating Costs: The ongoing costs of raw materials (ammonia, arsenic compounds), labor, energy, and maintenance.

- Revenue Generation: Revenue will be generated by selling ammonium arsenite to the agriculture, industrial, and chemical sectors.

- Profitability and ROI: A detailed financial analysis should be conducted to assess the return on investment (ROI) and profitability of the plant, considering production costs, market demand, and projected sales.

Media Contact

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au