In the world of luxury, details matter. Whether it’s a high-end watch, a rare collectible, or a premium cosmetic kit, presentation and protection are equally important. That’s where custom foam inserts come into play. At Custom Foam Parts, we specialize in crafting tailored foam solutions that not only protect your valuable items but also enhance their presentation. Our custom foam inserts are engineered with precision, ensuring your luxury items have a perfect fit every time.

Why Luxury Items Need Custom Foam Inserts

Luxury products are often delicate, valuable, and uniquely shaped. Standard packaging materials rarely provide the level of protection and presentation required to match the prestige of these items. Here’s why custom foam inserts are essential:

1. Maximum Protection

Luxury items like fine jewelry, limited-edition tech, and designer accessories demand superior safeguarding. Custom foam inserts cushion these valuables, absorbing shocks and preventing scratches, dents, or other transit-related damage.

2. Enhanced Aesthetic Appeal

Custom inserts not only protect but elevate the unboxing experience. The precision-cut foam adds a touch of sophistication, reflecting the premium quality of the item inside. It’s a silent ambassador of your brand’s attention to detail.

3. Perfect Fit Every Time

At Custom Foam Parts, we engineer inserts to the exact dimensions of your product. Whether it’s a single piece or an entire set, our foam is tailored to fit snugly—offering both security and sleekness.

Industries That Benefit from Custom Foam Inserts

We serve a variety of industries where product value and first impressions are paramount. Here are just a few that benefit most from our foam solutions:

● Luxury Watches and Jewelry

From diamond necklaces to Swiss-made watches, these items require both presentation and protection. Our velvet-lined foam options offer a secure and stunning display.

● High-End Electronics

Smartphones, premium earbuds, and limited-edition gadgets can be housed in custom inserts that maintain their pristine condition while also wowing the customer on unboxing.

● Cosmetics and Perfume Packaging

Delicate perfume bottles or high-end skincare kits benefit from die-cut foam that holds each item perfectly in place—preventing leakage or breakage.

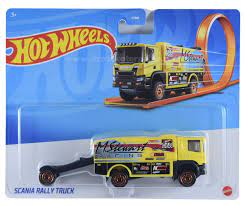

● Collector’s Items

Rare coins, autographed memorabilia, or vintage collectibles deserve packaging that respects their worth. Custom foam inserts help maintain their value for decades to come.

● Corporate Gifting and Sales Kits

Leave a lasting impression with custom-branded packaging. Foam inserts keep each promotional product organized, clean, and secure in transit.

Materials That Match the Luxury

We offer a wide range of foam materials to suit the aesthetics and needs of your brand and product:

● Polyethylene (PE) Foam

PE foam is durable and resistant to moisture, making it ideal for long-term storage and shipping of luxury items.

● Polyurethane (PU) Foam

This soft, flexible material is often used for delicate or fragile items. Its smooth texture is perfect for jewelry and cosmetics.

● EVA Foam

Known for its softness and form-fitting properties, EVA foam offers an upscale look with long-lasting reliability—great for retail displays and high-end cases.

● Custom Colors and Laminates

Want to match your brand’s aesthetic? Choose from a range of colors, textures, and even printed laminates that align with your product line.

Our Design Process at Custom Foam Parts

At Custom Foam Parts, we combine modern technology with decades of experience to deliver unmatched precision and quality. Here’s how we ensure a perfect fit every time:

1. Consultation & Product Review

We begin with a deep dive into your product’s size, shape, weight, and packaging requirements. Whether you’re working with CAD files or just a physical sample, we adapt.

2. Custom Design with CAD/CAM Software

Our design team uses industry-leading software to create 2D and 3D models of your foam insert. This ensures the cut is precise to the millimeter.

3. Prototyping

Before full production, we provide a prototype for your review. You can test the fit, feel, and functionality before committing to the final batch.

4. Final Production

Once approved, your foam inserts go into production using CNC cutting, waterjet, or die-cutting technologies. Whether you need 10 units or 10,000, we scale to meet your demand.

Why Choose Custom Foam Parts?

We understand that when you deal in luxury, you can’t afford to compromise on presentation or protection. Here’s why brands across the world trust us:

✅ Industry Expertise

With years of experience serving premium brands, we understand the nuances of packaging for luxury goods.

✅ Custom Solutions

No two luxury items are the same. We tailor our inserts precisely to your product—because excellence is in the details.

✅ Made in the USA

All our products are manufactured with strict quality control standards in our USA-based facility.

✅ Low MOQ & Fast Turnaround

Whether you need a few custom pieces for a limited edition launch or a full-scale rollout, we cater to projects of all sizes with quick lead times.

Testimonials

“Custom Foam Parts took our high-end product line to a whole new level. Our unboxing experience is now part of our brand story.”

— James L., Luxury Watch Manufacturer

“We’ve used other foam suppliers before, but none matched the precision and elegance that Custom Foam Parts delivered. Highly recommend!”

— Elena M., Designer Jewelry Brand

Frequently Asked Questions

Q1: Do you offer custom branding on the foam?

Yes! We can add your company’s logo or custom prints to the foam surface to reflect your brand identity.

Q2: What’s the minimum order quantity?

We have no minimum order quantity. Whether you need a single prototype or a full production run, we can accommodate your needs.

Q3: Can you help with the outer packaging too?

Absolutely. While we specialize in foam inserts, we can work with your box supplier or recommend partners to create a complete luxury packaging solution.

Q4: How long does it take to get a prototype?

Prototypes typically take 5–7 business days after finalizing the design. Rush services are available upon request.

Ready to Elevate Your Luxury Packaging?

Your luxury items deserve more than generic packaging—they deserve a custom foam solution crafted with care, precision, and premium materials. At Custom Foam Parts, we don’t just deliver foam; we deliver peace of mind and presentation that resonates.