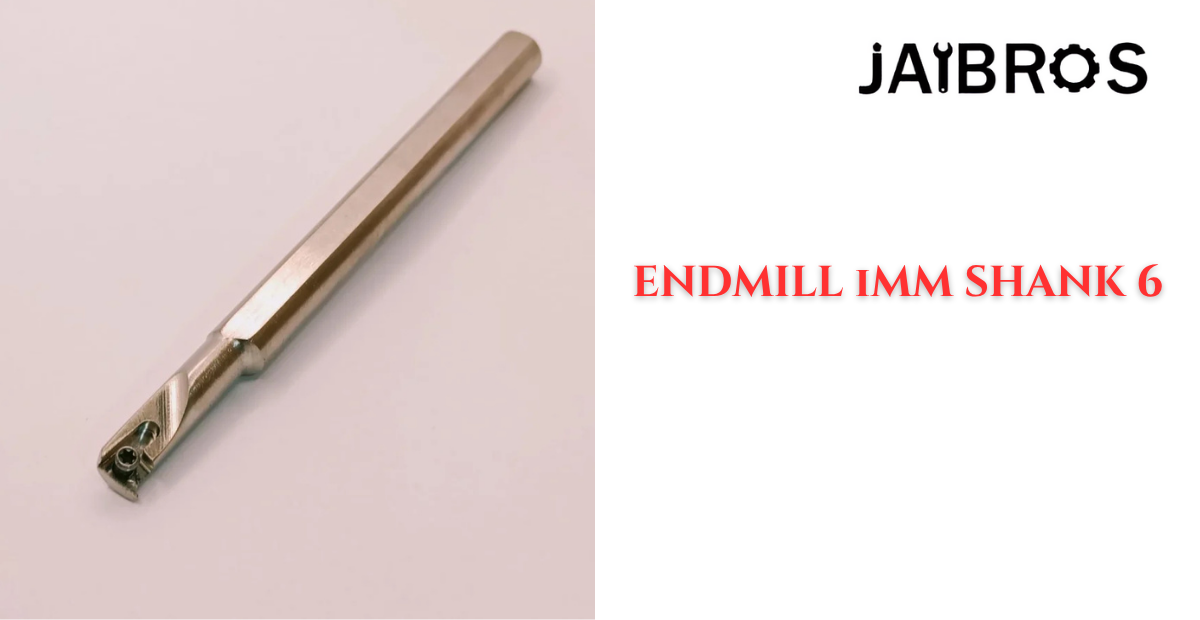

Discover the power of an endmill 1mm shank 6 — perfect for accurate milling, engraving, and shaping small parts in your CNC machine.

What is an Endmill 1mm Shank 6?

A cutting tool known as an endmill 1mm shank 6 is small in size and comes in a micro cutting tool for use in CNC milling machines, or CNC machining. The “1mm” refers to the diameter of the cutting end, while the “6” typically designates either the size of the shank from top to bottom on the tool or the length, depending on the model of endmill you select. This micro-endmill is perfect, especially for machining where precision cuts are needed for engraving, small cavity cuts, and even mold making.

The key advantage an endmill has over a normal drill bit is the ability to cut in multiple ways or directions; a drill bit cuts straight down, while an endmill can cut vertical, horizontal or diagonal. For example, endmills can be used in machining: hollowing shapes, contouring a surface or finishing the surface of machined metal or wood, or even in machining plastic.

Why Precision Matters in Small Endmills

The paramount factor when using an endmill 1mm shaft 6 is precision. Due to the extremely small tool diameter, even the smallest vibration or feed error can result in breakage or poor finish. This is why a high-speed spindle and a stable clamping system are important. Quality endmills are manufactured with carbide or coated material to resist heat and wear when performing high-speed cutting.

In delicate machining work, such as watch parts, electronic components, and medical devices, a small endmill can achieve perfect surface quality and accurate dimensions, which is not possible with larger tools.

Applications of Endmill 1mm Shank 6

The 1mm shank length endmill of 6 is used in several industries. Most common uses of this endmill are:

- Fine Engraving: This endmill is great for engraving fine letters, logos, and patterns on metals, wood, or plastics.

- Mold and Die Making: This endmill is used for making small molds, cavities, and fine details, on dies.

- Jewelry Design: This endmill is excellent for cutting detailed shapes and designs on gold, silver, or other metals.

- Electronics Manufacturing: This endmill is used for circuit board prototypes and cutting delicate components.

- Model Making and Prototyping: This endmill is great for small parts with the accuracy required, plus it finishes well.

The tool’s small size allows it to fit into tight areas while making a clean cut and minimizing further finishing work.

Material and Build Quality

When picking an endmill, the material choice will be an important factor with a 1mm shank 6. You will want to use solid carbide end mills as they provide strength, durability, and longevity. Other endmills will sometimes have coatings made of aluminum or titanium to lessen friction and the heat generated. High-speed steel (HSS) endmills are available for cutting into softer materials, but solid-carbide endmills are still the most used in industrial applications for their hardness and heat resistance.

The shank design of the endmills allows them to fit properly into any CNC collets or holders to minimize any vibration and assist with accuracy in cutting. Before you start cutting, always check the chamfer on the endmill shank and the spindle to a perfect fit to ensure an even more proper fit to minimize vibration when cutting.

Tips for Using a 1mm Endmill Effectively

When using micro endmills, one must be very cautious in setting up and also running them. Below are a few suggested items:

- Spindle Speed and Feed Rate: Micro endmills need a much higher spindle speed than a normal feed speed and a much slower feed speed. This way, you will prevent breakage, and tool life may also improve.

- Clamping: a good set-up will help eliminate your vibrations when running it, better surface finish as a result.

- Use of Coolant: cool down the part when running the endmill, which will help tool wear in the long run.

- Avoid Heavy Cuts. It is really always best to take multiple light passes rather than one heavy cut, so you know you are in control.

- Check Tool Continuously: Change out the tool if it gets dull; accuracy and finish will suffer if the tool becomes dull.

All these little things will help keep your endmill happy, and your .001 shank 6 will be consistent to finish.

How to Choose the Right Endmill for Your Work

The choice of which tool to utilize ultimately hinges upon multiple factors such as substrate material, machine ability, and cutting parameters. For smaller tools like the 1mm shank-endmill 6, you will want to consider:

- The Material of the Workpiece: Carbide endmills will be the best route for hard metals, and HSS will work for softer materials.Motion Mechanism: Coated tools will produce a better life and cut faster.

- Number of Flutes: More flutes will result in smoother finishes, while fewer flutes will lead to better chip evacuation.

- Length of Tool: Shorter tools will be more stable, thus creating less vibration.

If you are unsure which endmill to use, you can always turn to reliable online retailers like jaibros, that will have the specs of each product and only sell reputable industrial quality tooling.

Benefits of Using a Small Endmill

There are many benefits of using an endmill with a 1 mm shank:

- High Precision: Very suitable for careful and intricate applications.

- Smooth Surface Finish: Provides a smooth, clean surface cut edge.

- Minimal Material Waste: Controlled cuts without overcutting the material.

- Longevity: Carbide made for extended use.

- Adaptability: Metals, plastics, and non-ferrous materials.

In industries with an extreme emphasis on accuracy, like aerospace, electronics, or watchmaking, these types of tools are a necessity to use on a daily basis for machining.

Where to Buy Reliable Endmills

When you purchase specialty tools – such as the endmill 1mm shank 6 – look for reputable suppliers who are selling the original article with specifications. For instance, Jaibros.com has a selection of CNC and cutting tools for professional workshops and small companies. They carry tool holders, inserts, and accessories for better machining efficiencies as well.

When you purchase quality tools from trusted brands, you get better tool quality, and reliable delivery with support should you need it.

Frequently Asked Questions

Q1: What is an endmill 1mm shank 6 used for?

An endmill 1mm shank 6 is intended for fine detail CNC milling, engraving and delicate cutting work. It is beneficial if needing high precision and a smooth finish on small parts and components.

Q2: Can it cut hard metals?

An endmill 1mm shank 6 can cut through hard metals if it is made of carbide. The endmill should retain its sharpness and durability while reaching high-speed machining.

Q3: How long a life does it get with a 1mm endmill?

The life of a 1mm endmill depends on material, speed, and conditions of cutting. If used properly and using some coolant, carbides can typically provide many hours of use.

Q4: Is a coolant level required for 1mm endmills?

Yes, it is highly recommended. The coolant reduces the heat and friction, making for a smoother, longer-lasting cutting.

Q5: Where can I purchase this tool while in the country India?

You should be able to purchase online, check out Jaibros.com as a trusted resource for guaranteed quality.

Conclusion

The endmill 1mm shank 6 is a small but sturdy sized cutter for fine and detail work. This tool has become the cornerstone of modern precision machining processes, enabling industries to produce high-quality items with great precision. Whether you are creating molds, jewelry, or prototypes, this tool will provide you with great control, smooth finishes, and great value in the long run. If you depend on machine tooling, you should consider high-quality endmills from suppliers like Jaibros to ensure your shop operates at optimum efficiency and achieves the best results with every project.