Understanding the Importance of Alternating Current Filters

Electricity powers nearly every modern device—from industrial machines to the smartphone in your pocket. Yet, behind this seamless flow of energy lies a complex challenge: ensuring clean, stable, and interference-free current. This is where the alternating current filter (commonly called an AC filter) steps in.

At its core, an alternating current filter is designed to eliminate unwanted noise, harmonics, and voltage fluctuations in AC systems. Without this essential component, electrical disturbances can cause serious performance issues, shorten the lifespan of sensitive equipment, and even lead to costly downtime.

Companies like ODG recognize the importance of reliable AC filtering technology. With decades of experience and stringent quality standards, ODG ensures that every component they supply enhances stability and reliability across diverse applications—from consumer electronics to large-scale industrial operations.

How an Alternating Current Filter Works

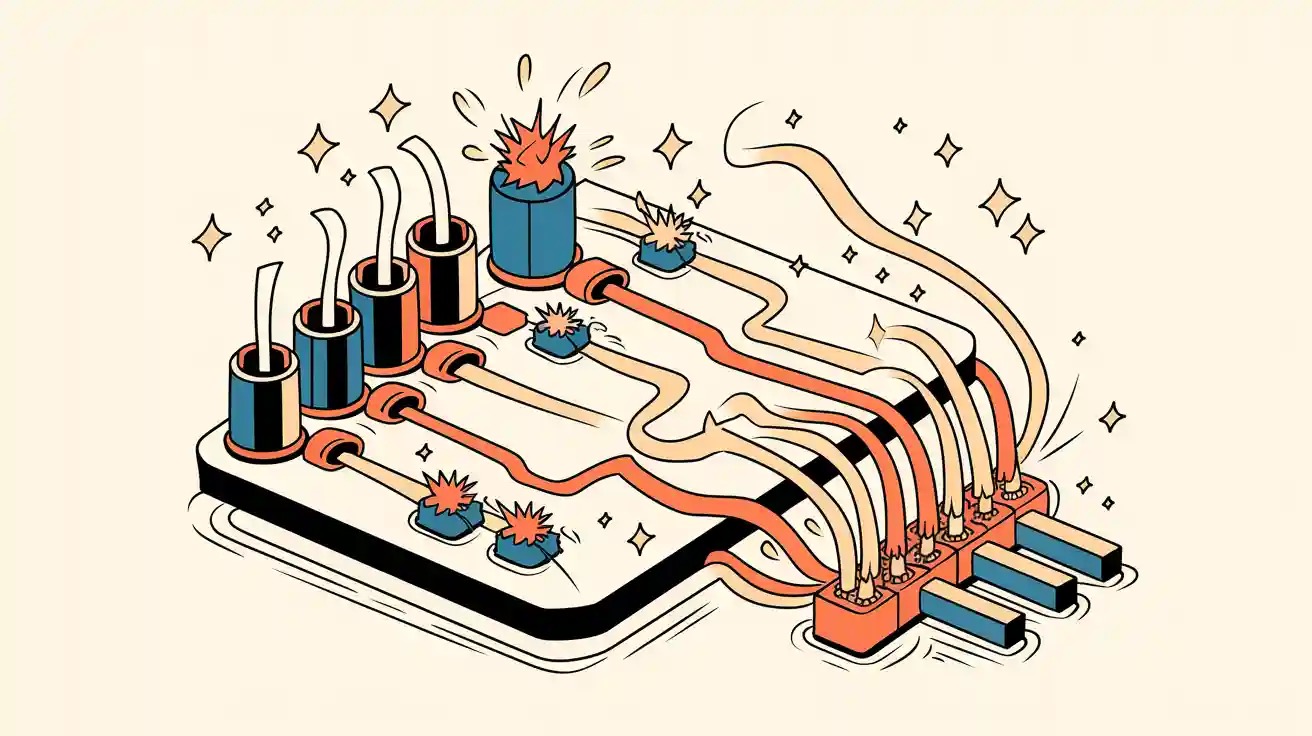

An alternating current filter operates much like a gatekeeper. It allows clean electrical signals to pass while blocking or reducing unwanted noise and interference.

When AC power flows through a circuit, it often carries high-frequency disturbances—commonly known as electrical noise—caused by other devices or environmental factors. The filter uses a combination of inductors, capacitors, and resistors to suppress these irregularities.

- Inductors block high-frequency noise by resisting sudden changes in current.

- Capacitors smooth voltage by absorbing spikes and stabilizing the flow.

- Resistors control the overall current balance, ensuring a steady output.

Together, these components maintain a clean, stable waveform—ensuring the connected system runs efficiently and safely.

Types of Alternating Current Filters

Not all filters are created equal. The choice of an AC filter depends on the specific needs of the system. Below are the most common types used across industries:

1. Passive AC Filters

These are the simplest and most widely used filters. They rely solely on passive components—capacitors, inductors, and resistors—to reduce harmonics and noise. Passive filters are cost-effective and require minimal maintenance, making them ideal for general applications.

2. Active AC Filters

Active filters use power electronics and digital control systems to dynamically counteract electrical noise. They can adapt to varying load conditions, offering greater accuracy in eliminating harmonics. These are commonly used in environments where high precision and performance are required, such as data centers or medical equipment.

3. Hybrid Filters

As the name suggests, hybrid filters combine both passive and active technologies. They provide the efficiency of passive filters with the responsiveness of active systems, striking a balance between performance and cost.

Applications Across Industries

The alternating current filter finds applications in nearly every sector that depends on electricity.

- Consumer Electronics: In televisions, computers, and audio systems, AC filters prevent interference that can distort sound or display quality.

- Industrial Machinery: Factories and automated systems rely on clean power for motors, sensors, and controllers. AC filters ensure these machines operate smoothly without interruptions.

- Renewable Energy Systems: Solar and wind energy installations use filters to stabilize fluctuating voltages and ensure seamless grid integration.

- Telecommunications: In network systems, filters eliminate electromagnetic interference (EMI) that can disrupt signal transmission.

Whether it’s a precision lab instrument or a production plant, reliable filtering ensures consistent performance and extended equipment lifespan.

Specifications and Key Considerations

When selecting an alternating current filter, engineers must evaluate a few critical specifications:

- Voltage and Current Rating: The filter must handle the maximum operating voltage and current without overheating.

- Frequency Range: Choosing a filter that effectively targets the frequencies of unwanted noise is essential for optimal performance.

- Insertion Loss: A measure of how much useful signal the filter blocks. Lower insertion loss means more efficient operation.

- Size and Mounting Options: Compact filters are preferred for space-constrained applications, while industrial systems may require heavy-duty units.

By carefully matching these specifications with the intended application, engineers can ensure long-term reliability and system stability.

The Role of Quality and Assurance at ODG

At ODG, quality is not just a metric—it’s a commitment. The company’s comprehensive Quality Assurance (QA) and Quality Control (QC) systems ensure that every alternating current filter meets the highest standards of reliability and performance.

ODG’s certifications, including AS9120B, ISO9001, ISO14001, ESD, and membership in ERAI, reflect its dedication to excellence and integrity. These standards guarantee that customers receive components built to last, no matter how demanding the environment.

Behind these achievements is ODG’s professional team, whose deep technical expertise allows them to understand customer challenges and offer customized filtering solutions. Whether it’s for an OEM partner or a global manufacturing firm, ODG’s focus on quality and customer satisfaction remains constant.

Maintenance and Troubleshooting Insights

Even the most reliable filters need regular attention to maintain optimal performance.

- Visual Inspection: Look for physical damage, corrosion, or burnt components.

- Check Connections: Loose or oxidized terminals can lead to voltage drops or increased resistance.

- Monitor Temperature: Overheating often indicates an overloaded or aging filter.

- Measure Output: Irregular readings in voltage or current signal potential filter degradation.

Routine maintenance not only prevents downtime but also extends the filter’s operational life—protecting both the equipment and the investment.

Emerging Trends in Alternating Current Filter Technology

Innovation continues to reshape how AC filters are designed and applied. Modern trends point toward smart filtering systems that integrate IoT and AI technologies. These intelligent filters can monitor real-time performance, predict maintenance needs, and automatically adjust parameters to maintain ideal operating conditions.

Additionally, as industries move toward renewable energy and electric mobility, filters must handle more complex and dynamic power environments. The next generation of alternating current filters will likely be smaller, more energy-efficient, and capable of adaptive noise suppression—further optimizing energy use and reliability.

A Step Toward a More Stable Electrical Future

Clean and stable power is not just a technical requirement—it’s a foundation for progress. The alternating current filter remains one of the most indispensable components ensuring that foundation stays strong.

With ODG’s unwavering dedication to quality, expertise, and innovation, industries worldwide can continue to depend on robust, noise-free power systems that drive performance and reliability. As technology advances, the role of AC filters will only grow more vital—guiding us toward a future where every watt of energy is clean, efficient, and dependable.

Follow ODG:YouTube: https://www.youtube.com/@Origin_Data

Facebook: https://www.facebook.com/OriginDataGlobalLimited Twitter: https://twitter.com/Origin_IC Tiktok:

https://www.tiktok.com/@origin_data Szxlxc:

https://www.szxlxc.com