A New Dawn in Agriculture

In a small industrial town where technology meets tradition, the story of an NPK compound fertilizer equipment manufacturer began. The founder, inspired by the challenges faced by local farmers, envisioned a future where advanced technology would bridge the gap between limited soil fertility and the ever-growing need for food production. In the early days, his workshop buzzed with creativity and determination, driven by the goal of transforming raw materials into a sustainable resource for agriculture. This marked the inception of what would later be known as revolutionary NPK Compound Fertilizer Equipment.

The Heart of Innovation: Inside the Production Facility

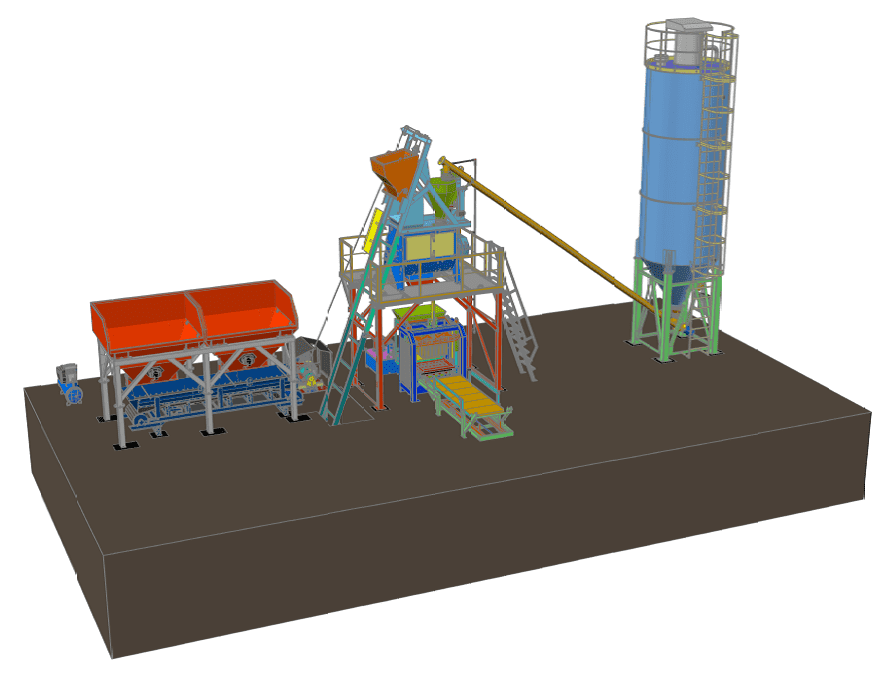

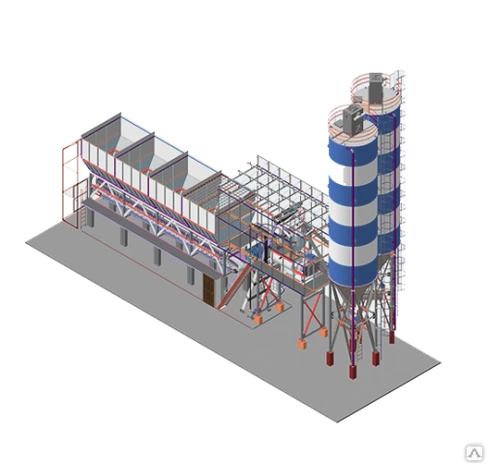

Walking through the modern facility of the manufacturer, one immediately notices the orchestration of advanced machinery and dedicated experts working in harmony. The plant is designed with cutting-edge NPK Compound Fertilizer Equipment that meticulously handles each step of the production process. Every machine, from the high-precision batching systems to the dynamic granulators, plays a critical role in creating a fertilizer that is both nutrient-rich and consistent.

Key Components in the Production Line:

- Batching Machines: These devices measure and mix raw materials with remarkable accuracy, ensuring the right proportions of nitrogen, phosphorus, and potassium.

- Mixers and Blenders: They homogenize the materials to achieve a uniform mixture, which is crucial for high-quality fertilizer production.

- Granulators: Transform the blended mixture into perfectly shaped granules, a process that simplifies storage and distribution.

- Dryers and Coolers: These machines reduce moisture, thereby enhancing the longevity and stability of the granules.

- Screening and Coating Machines: Ensure that only the best quality granules are packaged, with coatings that prevent nutrient loss during storage.

Revolutionizing Farming: The Manufacturer’s Journey

As the manufacturer grew, so did the impact of his innovations. Farmers in nearby regions began to notice the dramatic difference in crop yields. The fertilizer, produced by state-of-the-art NPK Compound Fertilizer Equipment, delivered balanced nutrition, significantly boosting plant growth. With enhanced vigor and resilience, crops thrived even in less-than-ideal soil conditions. This success story quickly spread beyond the local fields, catching the attention of agricultural communities nationwide.

The manufacturer’s success was not merely a tale of technical prowess; it was also a story of resilience and passion for sustainable agriculture. The equipment was continually refined to meet the evolving needs of modern farming, transforming the company from a small workshop into a leader in the fertilizer production industry.

Advantages of Advanced NPK Compound Fertilizer Equipment

The journey of this manufacturer illustrates several significant advantages brought about by modern NPK Compound Fertilizer Equipment:

1. Superior Crop Yields

Farmers using these fertilizers report remarkable improvements in crop performance. The balanced mix of nutrients directly addresses deficiencies in the soil, leading to healthier, more robust plants and ultimately higher yields.

2. Efficiency and Precision

The automated processes in the production line ensure that every granule of fertilizer is consistently mixed to perfection. This level of precision not only improves the quality of the fertilizer but also minimizes waste, making the production process highly efficient.

3. Customizable Solutions

Every crop and soil type is unique. The advanced equipment allows manufacturers to tailor the nutrient profile of the fertilizer to meet specific agricultural requirements. This flexibility enables farmers to optimize their crop production based on localized soil conditions and crop demands.

4. Cost-Effective Manufacturing

By integrating automation and digital controls, the production process becomes streamlined and less labor-intensive. This reduction in operational costs is a significant advantage for both the manufacturer and the end-users, the farmers, who benefit from competitively priced, high-quality fertilizers.

5. Enhanced Product Longevity

The granules produced by the equipment are designed for durability. They resist moisture absorption and degradation, ensuring that the fertilizer retains its effectiveness throughout storage and distribution.

Challenges and Disadvantages Along the Way

No innovative journey is without its hurdles. Despite the many advantages, the path of an NPK Compound Fertilizer Equipment manufacturer is marked by several challenges:

1. Environmental Concerns

While the fertilizer itself boosts crop production, its chemical composition and production process can have adverse effects on the environment. Over-reliance on chemical fertilizers may lead to soil degradation and water pollution through nutrient runoff. The manufacturer continuously seeks ways to mitigate these impacts by adopting cleaner production technologies and waste recycling measures.

2. High Capital Investment

Establishing a state-of-the-art production line involves significant upfront costs. The advanced machinery and automation systems require substantial investment, which can be a barrier for new entrants in the market. For the manufacturer, scaling operations while maintaining quality remains an ongoing challenge.

3. Fluctuations in Raw Material Supply

The production of NPK fertilizers depends heavily on the availability and cost of raw materials such as phosphate rock and natural gas derivatives. Global market fluctuations in these resources can affect production costs and pricing stability, impacting the overall competitiveness of the fertilizer.

4. Health and Safety Risks

Operating heavy machinery and handling chemical substances pose inherent risks. The manufacturer must adhere to strict health and safety regulations to protect workers from exposure to potentially harmful chemicals and to ensure a safe working environment.

Market Performance: A Thriving Global Landscape

The success story of the NPK compound fertilizer equipment manufacturer is deeply intertwined with the dynamic market performance of the fertilizer industry. In recent years, global demand for fertilizers has surged, driven by the pressing need to enhance food production for a growing population. Key market trends illustrate this upward trajectory:

1. Growing Global Demand

With the global population on the rise, particularly in developing nations, the demand for high-yielding crops has never been greater. Advanced fertilizers produced by modern NPK Compound Fertilizer Equipment play a pivotal role in meeting this need by providing essential nutrients to crops across diverse agricultural landscapes.

2. Technological Advancements

Ongoing innovations in production technology are revolutionizing the fertilizer market. Manufacturers are increasingly incorporating digital monitoring, artificial intelligence, and IoT (Internet of Things) systems into their production lines. These advancements not only enhance product quality but also improve operational efficiency and sustainability.

3. Competitive Market Dynamics

The fertilizer market is highly competitive, with manufacturers striving to balance cost, quality, and environmental impact. As a reputable NPK compound fertilizer equipment manufacturer, the company has carved out a niche by delivering customized solutions that cater to the precise needs of modern farmers. Its commitment to quality and innovation has allowed it to remain competitive in a rapidly evolving market.

4. Government Initiatives and Subsidies

In many countries, governments are actively supporting the agricultural sector by offering subsidies and incentives for the adoption of high-quality fertilizers. These policies have created a favorable market environment, spurring further growth in the production and use of NPK fertilizers.

The Future: Pioneering Sustainable Growth

Looking ahead, the future of NPK Compound Fertilizer Equipment appears promising. The manufacturer is actively investing in research and development to innovate even further. Future projects include the integration of nanotechnology to enhance nutrient delivery and the development of eco-friendly production methods that reduce environmental impact.

Eco-Friendly Innovations

In response to growing environmental concerns, the company is exploring ways to incorporate recycled materials and renewable energy sources into the production process. The aim is to create fertilizers that not only improve crop yields but also contribute to a healthier ecosystem.

Digital Transformation

The advent of digital technology offers exciting possibilities for the fertilizer industry. Enhanced monitoring systems and data analytics can lead to better production outcomes and more precise applications of fertilizer in the field. This digital transformation is set to drive the next wave of growth and efficiency in the industry.

Conclusion: Cultivating a Legacy of Innovation

The journey of an NPK compound fertilizer equipment manufacturer is more than just a tale of industrial success—it is a narrative of innovation, challenges, and continuous improvement. From its humble beginnings in a small workshop to becoming a key player in a global market, this story exemplifies how technology can transform agriculture. Advanced NPK Compound Fertilizer Equipment has not only revolutionized fertilizer production but has also empowered farmers worldwide to achieve greater productivity and sustainability.

In this evolving landscape, the blend of technology, efficiency, and environmental stewardship will determine the future of agriculture. As the manufacturer looks ahead, it remains committed to fostering sustainable practices, ensuring that the legacy of innovation continues to nourish the world for generations to come.