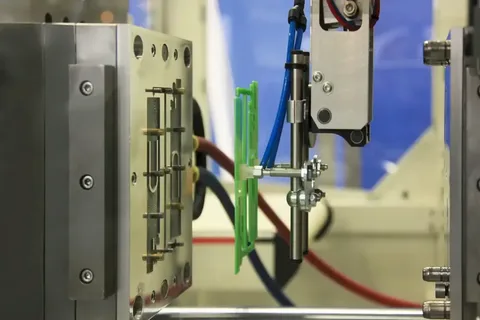

Plastic injection molding is a widely used manufacturing process that allows for the mass production of durable plastic components. This process involves injecting molten plastic material into a mold, where it cools and solidifies into the desired shape. The efficiency and precision of plastic injection molding make it the preferred choice for industries ranging from automotive to consumer electronics and medical devices.

One of the key advantages of using a plastic injection molding service is its ability to produce high-quality, durable products with consistent structural integrity. The combination of advanced materials, precise engineering, and innovative techniques ensures that products made using this process are resilient and long-lasting. This article explores how plastic injection molding contributes to enhanced product durability.

Use of High-Quality Materials for Enhanced Durability

A crucial factor in product durability is the choice of materials used in the injection molding process. Advanced plastic injection molding services offer a wide range of materials, including high-performance thermoplastics such as polycarbonate, nylon, and ABS. These materials possess superior mechanical properties such as impact resistance, tensile strength, and chemical stability, which contribute to the overall longevity of the final product.

Furthermore, plastic injection molding allows manufacturers to incorporate additives that improve durability. Reinforcements such as glass fibers, UV stabilizers, and flame retardants can be added to enhance the strength, heat resistance, and environmental stability of the molded components. By selecting the right materials and additives, plastic injection molding services ensure that products can withstand harsh operating conditions and prolonged use.

Precision Engineering for Structural Integrity

One of the primary advantages of a plastic injection molding service is the high level of precision it offers in manufacturing. Advanced mold design and computer-aided manufacturing (CAM) technology enable manufacturers to produce components with tight tolerances and uniform dimensions. This precision ensures that parts fit together seamlessly, reducing the risk of weak joints or structural flaws that could compromise durability.

In addition, plastic injection molding minimizes inconsistencies that often occur in traditional manufacturing methods such as machining or casting. The automated nature of the process reduces human error and enhances the repeatability of production. As a result, manufacturers can create products with superior strength and reliability, contributing to their long-term durability.

Enhanced Resistance to Environmental Factors

Products manufactured using a plastic injection molding service exhibit excellent resistance to various environmental factors, including moisture, temperature fluctuations, and chemical exposure. Many high-quality thermoplastics used in injection molding are designed to resist degradation from UV rays, corrosive substances, and extreme temperatures, ensuring long-lasting performance.

Additionally, the ability to customize the surface finishes and coatings of injection-molded parts further enhances their durability. Manufacturers can apply protective coatings or texturing techniques to increase resistance to scratches, wear, and external damage. These enhancements make plastic injection molding a reliable choice for industries requiring robust and resilient components, such as the aerospace and marine sectors.

Cost-Effective Durability Through Efficient Production

Plastic injection molding not only improves product durability but also does so in a cost-effective manner. The process allows for large-scale production with minimal material waste, making it more economical than traditional manufacturing methods. Since the molds used in injection molding are highly durable and reusable, manufacturers can produce consistent, long-lasting components without frequent tooling replacements.

Moreover, plastic injection molding services optimize production efficiency through automation. Automated processes ensure precise material distribution, controlled cooling rates, and uniform thickness in molded parts. This efficiency results in products with enhanced durability at a lower production cost, making it an ideal choice for businesses aiming to balance quality and affordability.

Conclusion

A plastic injection molding service plays a crucial role in improving product durability through material selection, precision engineering, environmental resistance, and cost-effective manufacturing. By leveraging high-quality thermoplastics and advanced molding techniques, manufacturers can create components that withstand wear and tear while maintaining structural integrity.

With industries demanding increasingly durable and reliable products, plastic injection molding remains the go-to solution for manufacturers seeking high-performance, long-lasting components. Whether for automotive parts, medical devices, or consumer electronics, the advantages of injection molding in enhancing durability make it an essential process for modern manufacturing.