As sustainability becomes a priority across manufacturing and distribution industries, companies are rethinking how products are packed and protected. Excess packaging, inefficient materials, and inconsistent wrapping processes often lead to unnecessary waste and higher operational costs. Modern packaging automation offers a solution by improving precision and material control. In many production environments, a shrink wrap packaging machine plays a vital role in reducing waste while maintaining product safety, visual appeal, and logistical efficiency throughout the supply chain.

Understanding Packaging Waste Challenges

Packaging waste typically results from overuse of materials, damaged goods, and inconsistent manual wrapping. Traditional packaging methods often rely on excessive plastic, cardboard, or fillers to compensate for a lack of precision. This not only increases waste but also raises transportation costs due to added weight and volume.

Another common issue is rework. Poorly wrapped products may arrive damaged, requiring repackaging or disposal. These inefficiencies contribute directly to landfill waste and higher carbon emissions. Automation addresses these challenges by delivering consistent and controlled packaging results.

Precision Wrapping for Material Efficiency

Accurate Film Usage

Automated shrink wrapping systems are designed to apply only the required amount of film to secure a product. Sensors and adjustable settings ensure the film fits closely around the item, eliminating unnecessary layers. This precision significantly reduces plastic consumption compared to manual methods.

By minimizing excess film, companies can lower raw material usage while still achieving durable packaging. Over time, these savings add up, reducing both environmental impact and operating expenses.

Consistent Package Integrity

Uniform wrapping ensures that every package meets the same quality standard. This consistency reduces the likelihood of loose packaging, torn film, or product exposure. Fewer damaged packages mean fewer returns and less need for repackaging, directly cutting down waste generation.

Streamlining Operations Through Automation

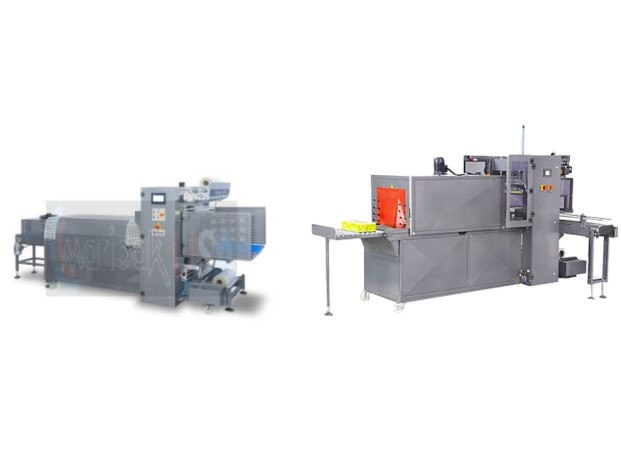

In the middle of the production process, integrating a shrink wrap packaging machine improves workflow efficiency. Automated systems synchronize with conveyors and sealing units, reducing human error and speeding up packaging cycles. Faster throughput means fewer stoppages and less material wasted due to mistakes.

Automation also supports better inventory management. When packaging is predictable and standardized, businesses can accurately forecast material needs and avoid overordering film or packaging supplies that may go unused or discarded.

Supporting Sustainable Packaging Practices

Compatibility With Thinner Films

Modern shrink wrapping equipment supports the use of advanced, lightweight films that provide strength with less material. These thinner films reduce plastic usage without compromising protection. Some options are also recyclable, helping companies align with sustainability goals.

Reduced Secondary Packaging

Shrink wrapping often eliminates the need for additional packaging elements such as boxes, straps, or fillers. Products can be bundled securely with minimal material, simplifying recycling and reducing waste at the consumer level.

Improving Logistics and Transportation Efficiency

Compact, tightly wrapped products occupy less space during shipping and storage. This improved density allows more units to be transported in a single shipment, reducing fuel consumption and emissions. Efficient packaging also minimizes movement during transit, lowering the risk of damage and waste.

In one of the final stages of the packaging line, a shrink-wrap packaging machine ensures products are stabilized and ready for distribution with minimal material use. This efficiency supports both environmental responsibility and cost-effective logistics.

Conclusion

Reducing packaging waste requires a combination of precision, consistency, and smart use of materials. Automated shrink wrapping systems deliver all three by minimizing excess film, preventing damage, and improving overall efficiency. As businesses continue to prioritize sustainability, investing in modern packaging solutions becomes a strategic decision. At the core of this process, the heat tunnel enables controlled shrinking that maximizes material efficiency while ensuring reliable product protection and long-term waste reduction.