A crucial choice that can greatly affect the effectiveness and performance of industrial operations is choosing the suitable heat transfer equipment. Choosing the correct heat exchanger and associated components has become more important than ever given the complexity of industrial operations and increased focus on energy economy. This thorough handbook investigates the key elements to take into account while choosing heat transfer equipment, therefore enabling industry professionals to make wise selections in line with their particular operating requirements and objectives.

Knowing Operating Conditions and Process Requirements

Choosing suitable heat transfer equipment starts with a comprehensive knowledge of process conditions and needs. This covers examining elements including fluid characteristics, flow rates, temperature ranges, and pressure needs. Every heat exchanger application has special qualities that have to be carefully assessed to guarantee best performance. The choice procedure ought to take into account possible future needs as well as present operational ones and process changes. Knowing the thermal duty, allowed pressure reductions, and temperature approach criteria allows one to narrow down appropriate equipment choices.

Heat Transfer Equipment Types and Uses

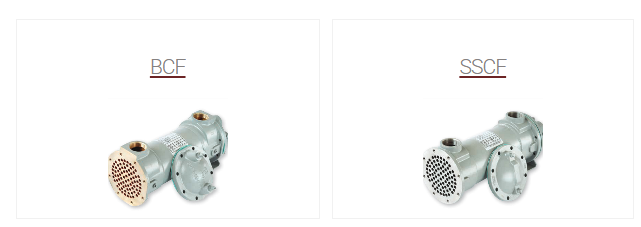

To get best outcomes from different industrial processes, particular kinds of heat transfer equipment are needed. While plate heat exchangers provide great efficiency in small designs, shell and tube heat exchangers have strong performance for high-pressure uses. Every kind of heat exchanger has benefits and drawbacks, so they are appropriate for different uses. In places where water is limited, air-cooled heat exchangers could be chosen; spiral heat exchangers shine in managing highly viscous fluids. Knowing these features helps one to match equipment capacity with process requirements. The choice should weigh operational flexibility, heat transfer efficiency, and maintenance needs.

Material Choices and Compatibility Issues

The performance and lifetime of heat transfer equipment are strongly influenced by the materials used for it. Various process fluids may call for particular components to guarantee long-term dependability and prevent corrosion. When choosing a heat exchanger, one has to take into account elements such pressure ratings, chemical compatibility, and temperature restrictions. The process of choosing materials should strike a balance between predicted service life and maintenance needs against first expenses. Applications involving corrosive fluids, high temperatures, or frequent thermal cycling should especially be given special focus. The whole lifetime cost of the equipment can be much influenced by the materials chosen correctly.

Efficiency Factors and Performance Enhancement

Maximizing heat transfer equipment performance calls for thorough evaluation of several design and operating aspects. To get the required heat transfer rates, this covers maximizing flow arrangements, heat transfer surface area, and fluid velocities. Appropriate heat exchanger designs must be chosen with regard for hydraulic and thermal performance criteria. Equipment choice depends much on factors including fouling resistance, pressure drop constraints, and energy efficiency targets. Another crucial factor is being able to keep constant performance under different running environments.

Space and Installation Need:

Heat transfer equipment is chosen in great part depending on physical limits and installation issues. Various kinds of heat exchangers demand different spaces and installation requirements. One should carefully consider the floor space, headroom, and maintenance access that are at hand. One should also give thought to weight constraints and foundation needs. Certain applications could call for particular orientation or unique mounting configurations, therefore influencing the equipment selection. The whole cost of ownership can be much influenced by installation expenses and access to simplicity of maintenance.

Aspects of Serviceability and Maintenance

Reliability of heat transfer equipment throughout long run depends on regular maintenance. Maintenance needs and cleaning techniques differ among the several kinds of heat exchangers. The choosing process should take access for cleaning, maintenance, and inspection activities into account. Because of fouling tendencies, some applications could need regular cleaning; so, ease of maintenance becomes quite important. Furthermore affecting the choice should be the availability of local service assistance and spare parts. Simple maintenance tools for equipment help to greatly lower running expenses and downtime.

Economic Research and Lifelong Costs

Selecting heat transfer equipment calls for a thorough economic study. This ought to cover long-term running expenses as well as initial outlay charges. The study should take into account elements such projected service life, energy use, maintenance expenses, and possible downtime expenses. Although certain heat exchangers have more starting costs, their greater efficiency and low maintenance requirements help to provide better long-term value. The lifetimes cost study should also consider the availability and cost of spare parts.

Safety and Environmental issues

Heat transfer equipment choice calls for rigorous evaluation of environmental impact and safety criteria. Equipment should follow pertinent safety criteria and environmental laws. One has to take into account elements such possible fluid leakage, noise levels, and pollutants. Certain uses might call for particular certifications or safety features. Energy efficiency and end-of- life disposal issues should be among the factors of potential environmental impact of various equipment kinds under evaluation.

Conclusion

The choice of suitable heat transfer equipment is a complicated process requiring careful attention of several elements, including process requirements, operating circumstances, maintenance demands, and financial constraints. The effective and dependable execution of these key components determines the success of industrial activities most of the times. By means of a methodical approach to choice considering all pertinent criteria, one can guarantee best performance and value during the lifespan of the equipment. Understanding these sophisticated needs, Kinetic Engineering Corporation provides professional advice on choosing and using the most suitable heat transfer technologies for different industrial uses, therefore guaranteeing best performance and long-term dependability.