Manufacturers navigating the world of plastic production know that precision, durability, and scalability are non-negotiable. At the heart of many plastic applications—from packaging to construction—lies a crucial component: the PET sheet. Ensuring the quality and consistency of these sheets starts with one key piece of equipment: the PET sheet making machine. This article unpacks what makes this machine indispensable, how it operates, and why SIVITE’s technology is trusted across industries and continents.

Why the PET Sheet Making Machine Matters

PET (Polyethylene Terephthalate) is a thermoplastic polymer known for its clarity, strength, and excellent barrier properties. PET sheets are widely used in food packaging, electronics, automotive interiors, and medical applications. The global demand for PET sheets is growing, driven by sustainability concerns and the shift toward recyclable materials. With this surge, companies are seeking equipment that delivers quality at scale, minimizes waste, and ensures energy efficiency. That’s where the PET sheet making machine becomes critical.

This machine is not just another piece of factory equipment—it’s the engine behind smooth, consistent, and high-performance sheet production. For businesses looking to stay competitive, investing in the right PET sheet making system means better control over cost, product quality, and production timelines.

What Sets SIVITE Apart in PET Sheet Manufacturing

Established in Dongguan—fittingly dubbed the “World Factory”—Guangdong SIVITE Intelligent Manufacturing Co., Ltd. has built a solid reputation since 2010 for providing cutting-edge plastic machinery. Specializing in PET, PP, PLA plastic sheet extruders and fully automatic thermoforming machines, SIVITE combines deep engineering expertise with a sharp focus on innovation.

Their PET sheet making machines stand out for several reasons:

- Advanced Engineering: With nearly a decade of hands-on industry experience, SIVITE’s engineering team ensures each machine delivers maximum operational efficiency and minimal downtime.

- Global Recognition: Their products meet rigorous standards, holding both EU CE and ISO certifications, making them suitable for global markets.

- Innovation Through Patents: SIVITE has developed over 20 invention patents, signaling their commitment to pushing the limits of what plastic manufacturing machinery can achieve.

- International Reach: With exports to over 80 countries and a client base of more than 1,500, SIVITE machines have proven reliability in diverse operating environments.

Inside the PET Sheet Making Machine: How It Works

Understanding the inner workings of a PET sheet making machine helps illustrate why it’s such a powerful tool for manufacturers. The machine typically follows a multi-stage process:

- Raw Material Feeding: Virgin PET pellets or recycled PET flakes are fed into the system via a hopper.

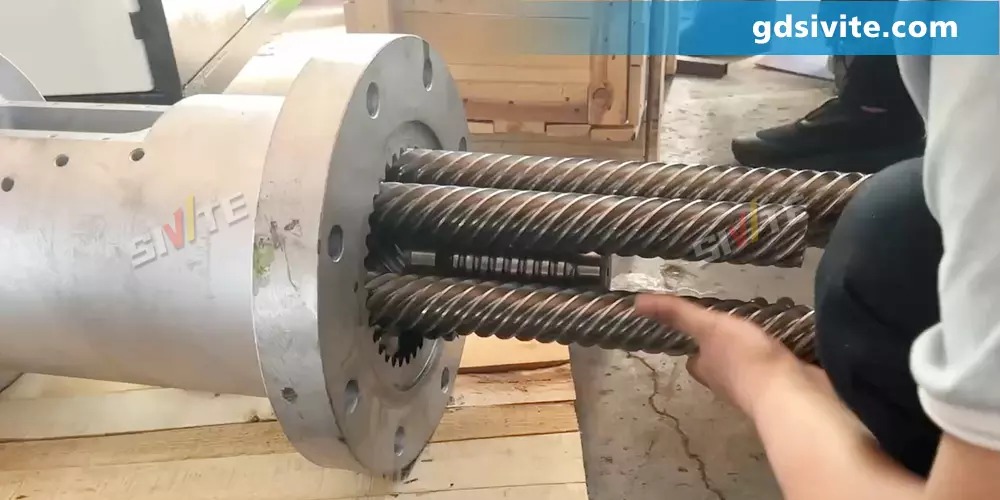

- Extrusion Process: The material is heated and pushed through a single- or twin-screw extruder, which melts and homogenizes the plastic.

- Sheet Formation: The molten PET passes through a flat die to form a thin, uniform sheet. Thickness is controlled to exact specifications here.

- Calendering & Cooling: The sheet is passed through chilled rollers (calendering process) to refine its surface and thickness, then cooled rapidly.

- Haul-Off and Winding: The finished sheet is pulled at consistent speed and wound onto rolls, ready for further processing or shipment.

Each stage is automated for precision, reducing human error and increasing consistency in sheet quality. SIVITE’s machines take this a step further with user-friendly digital interfaces, energy-efficient designs, and adaptive controls that respond to real-time data.

Why PET Sheet Production Is the Future

The global pivot toward sustainability has put PET at the forefront of plastic materials. PET is 100% recyclable, has a low carbon footprint, and retains high performance in reuse cycles. As environmental regulations tighten and consumer preferences shift toward sustainable packaging, companies must equip themselves to meet this new standard.

SIVITE’s PET sheet making machines support this shift by enabling the use of recycled PET (rPET) without compromising on quality. Their systems are optimized to handle both virgin and recycled materials, which offers manufacturers flexibility in sourcing and production planning.

Furthermore, the machines are designed to minimize scrap and reduce energy consumption, aligning economic objectives with environmental responsibility.

Applications That Go Beyond Packaging

While food packaging is the most visible application, PET sheets have penetrated various industries:

- Electronics: Used as insulating materials and component covers due to their electrical resistance and heat tolerance.

- Automotive: Offers lightweight, impact-resistant panels that help reduce vehicle weight and improve fuel efficiency.

- Construction: Utilized in clear roofing panels, interior decor, and protective layers.

- Medical: PET’s non-reactive nature makes it ideal for sterile packaging and protective barriers.

The versatility of PET demands machinery that can produce sheets to precise requirements across different grades and finishes. This is where SIVITE’s flexibility-focused engineering really shines—offering customizations for specific industry needs.

How SIVITE Enhances Manufacturer Competitiveness

The machinery you choose reflects your production strategy. A high-quality PET sheet making machine doesn’t just make plastic—it transforms your entire manufacturing approach. SIVITE ensures this transformation happens seamlessly.

Here’s how:

- Reduced Downtime: Machines are engineered for long-term stability, with minimal maintenance needs.

- Rapid ROI: Energy savings and reduced material waste accelerate return on investment.

- Future-Proof Designs: Compatibility with upcoming biodegradable materials like PLA ensures long-term relevance.

- Training and Support: SIVITE offers comprehensive after-sales support, technical training, and customized upgrades, helping clients get the most from their investment.

A machine is only as good as the company behind it—and SIVITE’s track record speaks volumes.

The Path Ahead for Manufacturers

Innovation in plastic sheet production is no longer optional. Manufacturers who prioritize speed, flexibility, and sustainability are not only meeting today’s demands but also building resilience for tomorrow. With PET continuing to dominate markets globally, choosing the right equipment partner could determine whether your business merely survives—or leads.

What possibilities would open up if your production line operated at peak efficiency, with less waste and more versatility? The answer may lie in the next generation of PET sheet making machines—built not just for performance, but for transformation.