In the realm of CNC and manual machining, accuracy should be everything. The slightest error could compromise structural strength or create flawed parts, costing businesses. An edge finder solves the problem, serving as a key assistant in helping machinists find the edge of a workpiece with extreme precision.

What Is an Edge Finder?

Edge finders, also called center finders and wigglers, are used when machining to find the edges, centers, or extremely accurate on the surface of a workpiece. The tool typically works with mills or lathes and is indispensable in a job requiring highly accurate measurements.

An edge finder is typically cylindrical and can be mechanical or electronic. Positioned in the spindle, it will be spun into rotation with a low RPM. The spinning process tests the air, and at any moment that it brushes the exciter of the workpiece, it shifts or “jumps” just a smidgen—the edge was hit.

Types of Edge Finders

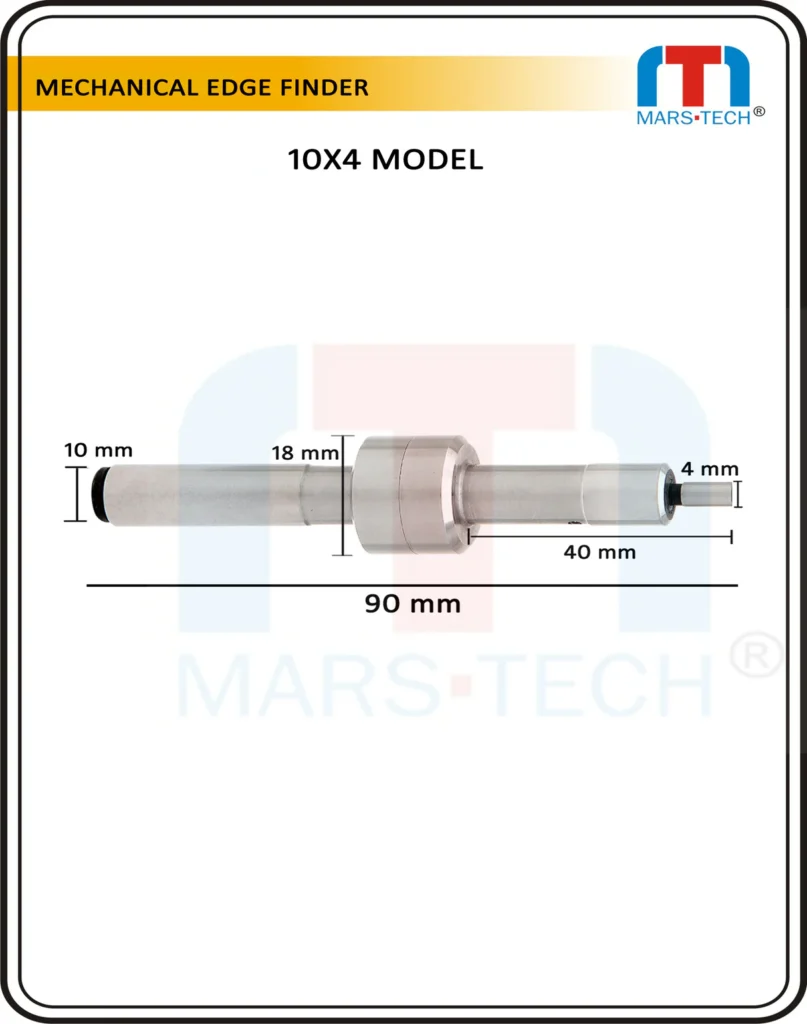

Mechanical Edge Finder

The tip is spring-loaded, which makes it wobble and fall into alignment while touching the surface.

It comes in an array and is also less expensive.

Electronic Edge Finder

Lights up or beeps during contact.

Applicable to low-energy places or fragile setups.

Laser Edge Finder

Projects a laser line across the workpiece.

Used to help the simpler setups, but not very accurate compared to the mechanical or electronic versions.

Why Use an Edge Finder?

Boost Accuracy: Sometimes there is no other way where alignment would be crucial.

Save Time: Setup is fast, with great repeatability guaranteed.

Eliminate Errors: Nosedive and removing the risk of misaligned cuts and drills.

Increase Tool Life: Proper alignment means a smoother cut, wearing out quickly.

Applications of Edge Finders

Setups on CNC milling machines

Jobbing in manual milling machine setups

Center finding on holes

Finding corners of a part

Setting zero points on fixtures

Regardless of whether it is mold, die, or aero component, the right origin is set by an edge finder for every job.

How to Use a Mechanical Edge Finder

Mount the Tool: Put the edge finder in the spindle or collet.

Slowly Spin: Run the spindle around the 500–1000 RPM level.

Bring Toward the Edge: Gently move the table toward the tool until it intersects the edge of the workpiece.

Watch for Jumping: This going-side becomes accurately lined up and suddenly gives off a “kick” while touching against the workpiece—thence marking the edge.

Set Zero: Move the table with a distance reaching half of the tip diameter to the right side to have some zero point.

Choosing the Right Edge Finder

Consider these factors when selecting an edge finder:

Type of machine (manual or CNC)

Material of the workpiece

Level of precision required

Visibility of setup

Generally, a mechanical edge finder can suffice for most situations. Electronic and laser edge finders are typically the way to go for high-precision work or automation.

FAQs on Edge Finders

Q1. Can edge finders be used on all-workpiece materials?

Yes, but with the most accuracy in conductive and smooth metal. In the case of not-so-smooth or non-conductive materials; the best option would be the laser or electronic finders.

Q2. At what spindle speed is an edge finder expected to be used?

Measured at 500 to 1000 RPM. Rapid rotation may damage the tool, while a rotation speed that is too slow may not produce the required “kick.”

Q3. Is an electronic edge finder more accurate?

Ease of use and consistency reduce human error, which may be regarded as the same level of accuracy or an improvement for a mechanical edge finder in proper usage.

Q4. Can edge finders be used on a CNC machine?

Yes. Edge finders are extensively used on CNC machines during setup for precise part alignment.

Q5. How should edge finders be maintained?

Maintaining cleanliness and avoiding dropping are key steps for edge finders. It is often advised to keep it safe and secure either in a box suppressing shock.

Final Thoughts

An Edge Finder may look tiny but has a massive impact on machining accuracy. Professionals and hobbyists alike will benefit, for sure, when setting up a machine installation and determining its accuracy with this edge finder. Whether you are aligning a CNC machine or squaring up on a manual mill, make sure this edge finder forms a part of your essential toolkit.