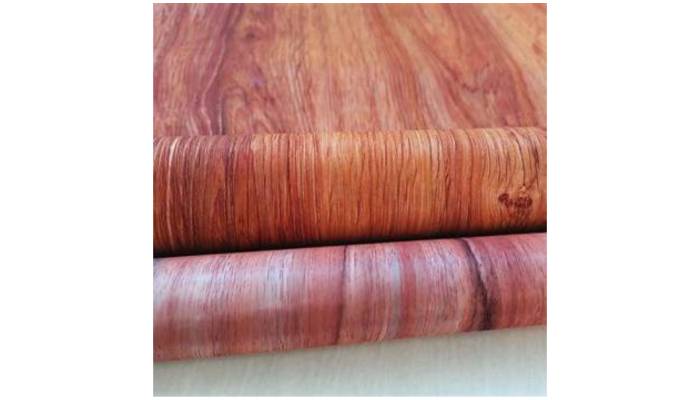

In the world of interior design and architectural aesthetics, materials that offer the perfect blend of beauty, durability, and cost-efficiency are in high demand. One such innovation gaining popularity is Wood Decorative Sublimation Films. These films mimic the natural look and texture of wood while offering flexibility and customization that traditional wood simply cannot match. Ideal for furniture, wall panels, ceilings, doors, and more, sublimation films are transforming the way we approach wood finishes.

What Are Wood Decorative Sublimation Films?

Wood decorative sublimation films are specialized transfer films used in a process called sublimation printing. This technique involves transferring dye onto surfaces like aluminum, stainless steel, MDF, PVC, or powder-coated metal through heat and pressure. The result is a highly realistic woodgrain finish that closely resembles natural wood in both appearance and texture.

How Does the Sublimation Process Work?

- Design Printing: The wood grain pattern is first printed onto a sublimation transfer film using high-quality sublimation inks.

- Wrapping: The printed film is then wrapped around or placed on the desired substrate.

- Heat Transfer: The wrapped substrate is placed in a vacuum or heat press where high temperature and pressure vaporize the ink and infuse it into the surface.

- Final Result: Once cooled, the film is removed, revealing a vibrant, wear-resistant wood-like finish that’s permanently bonded to the surface.

Key Benefits of Wood Decorative Sublimation Films

1. Realistic Aesthetic Appeal

These films can replicate a wide range of wood species — from oak and walnut to teak and mahogany — with remarkable accuracy. The texture, grain, and even knots of real wood can be mimicked.

2. Cost-Effective Alternative

Compared to natural wood or veneer, sublimation films offer a significantly more affordable option without compromising on visual quality.

3. Durability and Resistance

Sublimated surfaces are resistant to:

- Scratches

- Moisture

- UV rays

- Fading

- Corrosion (especially when applied on metal)

This makes them ideal for both indoor and outdoor applications.

4. Eco-Friendly

Since the process reduces the need for actual wood, it contributes to forest conservation. Additionally, substrates like recycled aluminum or MDF can be used, further enhancing sustainability.

5. Customization & Flexibility

Manufacturers can create bespoke designs tailored to specific themes or branding. The films can be applied to a wide range of shapes and materials, making them suitable for custom furniture and architectural elements.

Applications of Wood Sublimation Films

- Architectural Cladding & Facades

- Furniture (Tables, Cabinets, Shelves)

- Doors and Window Frames

- Wall Panels and Ceilings

- Elevator Interiors

- Retail Displays and Signage

- Interior Automotive Trim

Market Trends and Future Outlook

As demand for sustainable and aesthetic materials rises, wood sublimation films are expected to become a staple in both residential and commercial design. Innovations in ink technology and heat transfer methods continue to enhance the quality and efficiency of sublimation processes, promising even more realistic and longer-lasting finishes.

Conclusion

Wood Decorative Sublimation Films are revolutionizing the way designers, manufacturers, and consumers think about wood finishes. By offering a perfect balance between beauty, practicality, and sustainability, they provide a smart solution for modern interiors and exteriors alike. As technology continues to evolve, these films are poised to become an even more integral part of the architectural and design landscape.